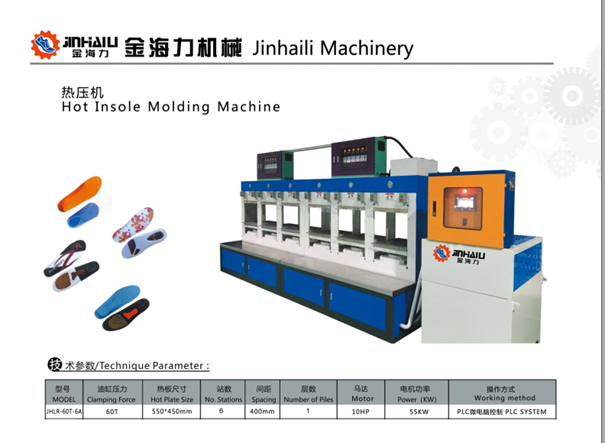

The Hot Insole Molding Machine is an essential device in the footwear manufacturing process, specifically for shaping and molding insoles using heat. With modern design and advanced technology, the machine provides an optimal solution for producing insoles with high precision and uniformity, while ensuring maximum production efficiency.

This machine can mold multiple products simultaneously with specially designed molds, reducing production time and costs. It uses an advanced PLC control system to monitor and adjust temperature and pressure precisely, ensuring stable product quality that meets the highest standards.

With the ability to shape insoles with high quality, uniformity, and durability, the Hot Insole Molding Machine is an ideal choice for footwear manufacturers looking to enhance production efficiency and product quality.

Key Features:

- High Pressure Force: The machine features a 60T clamping force, ensuring uniform and strong compression for insoles.

- Number of Molds: The machine is equipped with 6 molds, allowing simultaneous production of several pairs of insoles, increasing productivity.

- PLC Control: The PLC control system allows for precise monitoring and adjustment of the molding process, making it easy to operate.

- Uniform Temperature: The machine utilizes heating technology to maintain a consistent temperature in the mold, ensuring high-quality and durable insoles.

- Versatility: Suitable for various types of insoles, especially for sports and walking shoes.